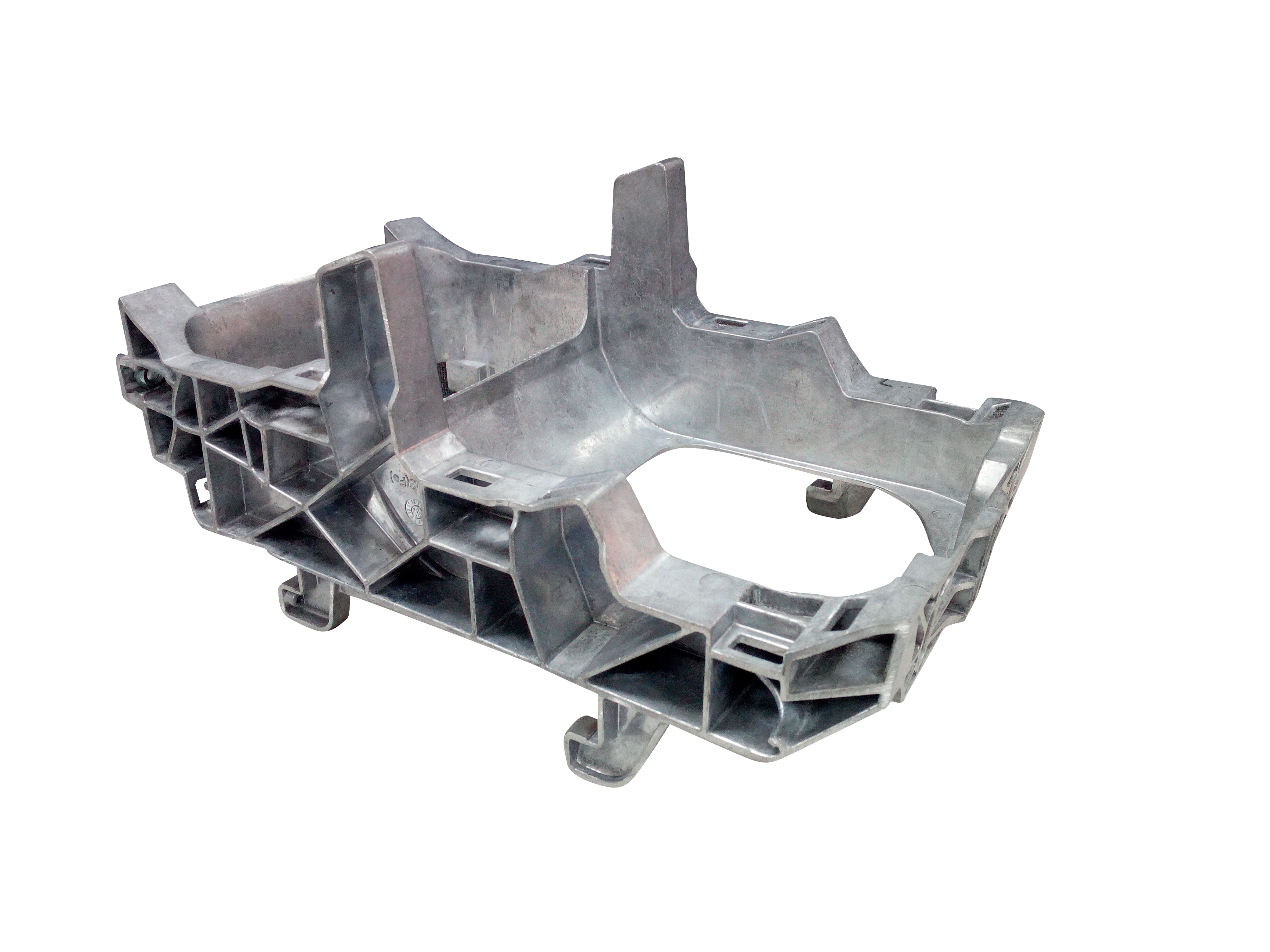

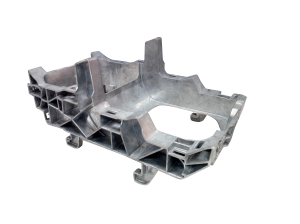

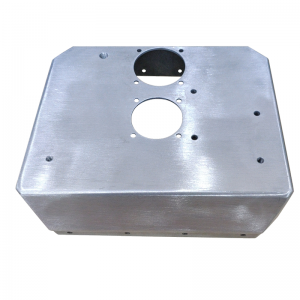

Aluminium dhuwur meksa die casting basa kanggo auto parts

Detail Produk

| Ngolah | Tekanan dhuwur die casting dening mesin kamar kadhemen Trimming Deburring Ditembak blasting Polishing lumahing Mesin CNC, nutul, ngowahi Degreasing Pemriksaan kanggo kabeh ukuran utamane ukuran tombol |

| Mesin | Die casting mesin saka 250 ~ 1650tonsMesin CNC 130 set kalebu merek Brother lan LGMazakMesin bor 6 set Mesin tapping 5 set Garis degreasing otomatis Garis impregnasi otomatis Ketebalan udara 8 set Garis lapisan bubuk Spektrometer (analisis bahan baku) Mesin Pengukur Koordinat (CMM) Mesin sinar X-RAY kanggo nguji bolongan udara utawa porositas Penguji kekasaran Altimeter Tes semprotan uyah |

| Aplikasi | Housing aluminium, kasus motor, kasus baterei kendaraan listrik, tutup aluminium, omah gearbox lsp. |

| Format file sing ditrapake | Pro/E, Auto CAD, UG, Solid work |

| Wektu timbal | 35-60 dina kanggo jamur, 15-30 dina kanggo produksi |

| Pasar ekspor utama | Eropa Barat, Eropa Timur |

| Kauntungan perusahaan | 1) ISO 9001, IATF16949, ISO140002) Bengkel die casting lan powder coating sing diduweni 3) Peralatan canggih lan Tim R&D sing apik 4) Proses manufaktur sing trampil banget5) macem-macem macem-macem produk ODM & OEM 6) Sistem Kontrol kualitas sing ketat |

Prosedur Produksi Die Casting

1. Inquiry- Priksa kabeh syarat wis cetha -->

2. Kutipan adhedhasar gambar 2D lan 3D-->

3. Purchase Order Released-->

4. Desain cetakan lan masalah produksi dikonfirmasi --->

5. Mold nggawe-->

6. Part Sampling-->

7. Sampel Disetujui-->

8. Produksi massal--->

9. Pangiriman bagean

Die Castings FAQ

1. Apa sing Bedane Antarane Aluminium Die Casting vs Sand Casting?

Bentenipun paling pinunjul antarane die casting lan wedhi casting punika cetakan-making materi. Casting aluminium nggunakake cetakan sing digawe saka paduan aluminium. Ing sisih liya, pengecoran pasir nggunakake cetakan sing digawe saka pasir.

Pengecoran pasir bisa digunakake kanthi desain sing luwih rumit. Ing tangan liyane, die casting nawakake akurasi luwih dimensi lan kacepetan.

Bentenane penting liyane yaiku, pengecoran pasir ngasilake tembok sing luwih kandel, dene pengecoran mati bisa ngasilake tembok sing luwih tipis. Mulane, wedhi casting ora becik kanggo bagean cilik.

Kacepetan produksi minangka prabédan penting ing antarane rong teknik kasebut. Perkakas die casting minangka tugas sing rumit lan mbutuhake wektu sing akeh. Ing tangan liyane, wedhi casting perkakas proses prasaja lan mbutuhake wektu kurang saka die casting.

Die casting becik kanggo produksi skala gedhe kaya yen sampeyan butuh ewu bagean. Nanging wedhi casting becik kanggo produksi skala cilik kaya 100-150 Unit.

2. Carane Larang punika Aluminium Casting?

Casting aluminium minangka salah sawijining proses die-casting logam sing paling larang. Sanajan perkakas die casting mbutuhake wektu luwih akeh, sampeyan bisa nggawe ewu unit kanthi siji cetakan. Sing luwih akeh sampeyan ngasilake, luwih murah dadi rega unit sampeyan. Aluminium luwih murah tinimbang stainless steel lan rada luwih larang tinimbang baja karbon.

3. Carane cepet proses die casting?

Die casting minangka proses casting otomatis. Perlu sawetara wektu kanggo nggawe cetakan. Nanging jamur bisa ngalangi paduan aluminium kanthi cepet. Lan minangka proses otomatis, mesin bisa ngasilake pirang-pirang unit tanpa istirahat. Mulane, die casting proses cepet utamané nalika sampeyan Manufaktur nomer ageng bagean.

Tampilan pabrik kita

We have full services except above processing ,we do the surface treatment in house including sandblasting ,chorme plating ,powder coating etc . our goal is to be your preferred partner , welcome to send us the inquiry at info@kingruncastings.com